-

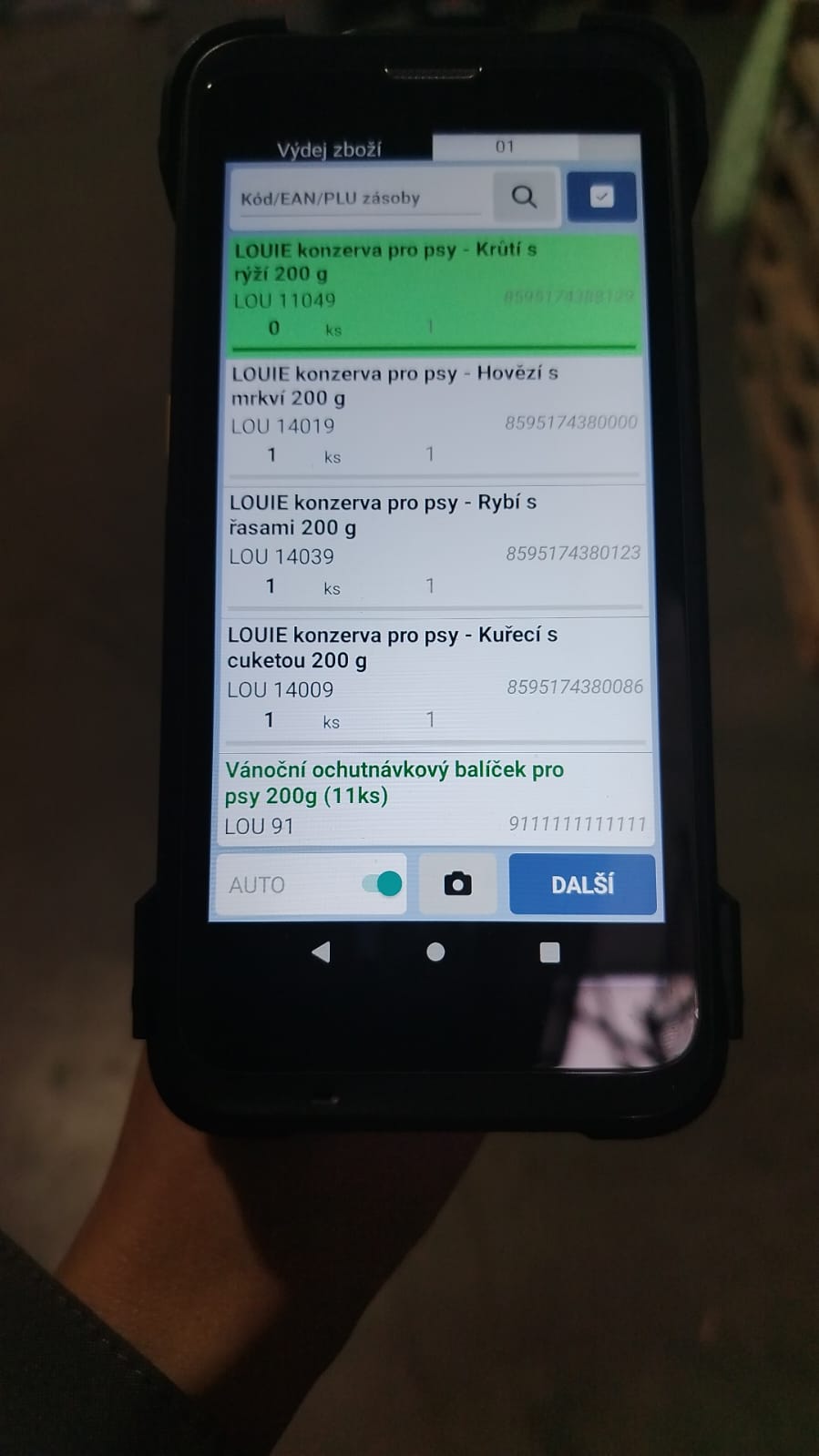

Saturday’s warehouse shift was boosted by the CSO and CEO 🙂

To boost the morale of the 12 colleagues in the warehouse, who received five times as many orders as a week ago, CSO Martin Baierle and company founder Martin Ioan Košt’ál took part in today’s Saturday shift as “pickers”. 🙂

-

The warehouse has reached shipments approaching 500 shipments per day!

We have increased our warehouse capacity to meet the demand from our online shop. Currently, our shipments are already approaching 500 shipments per day!

-

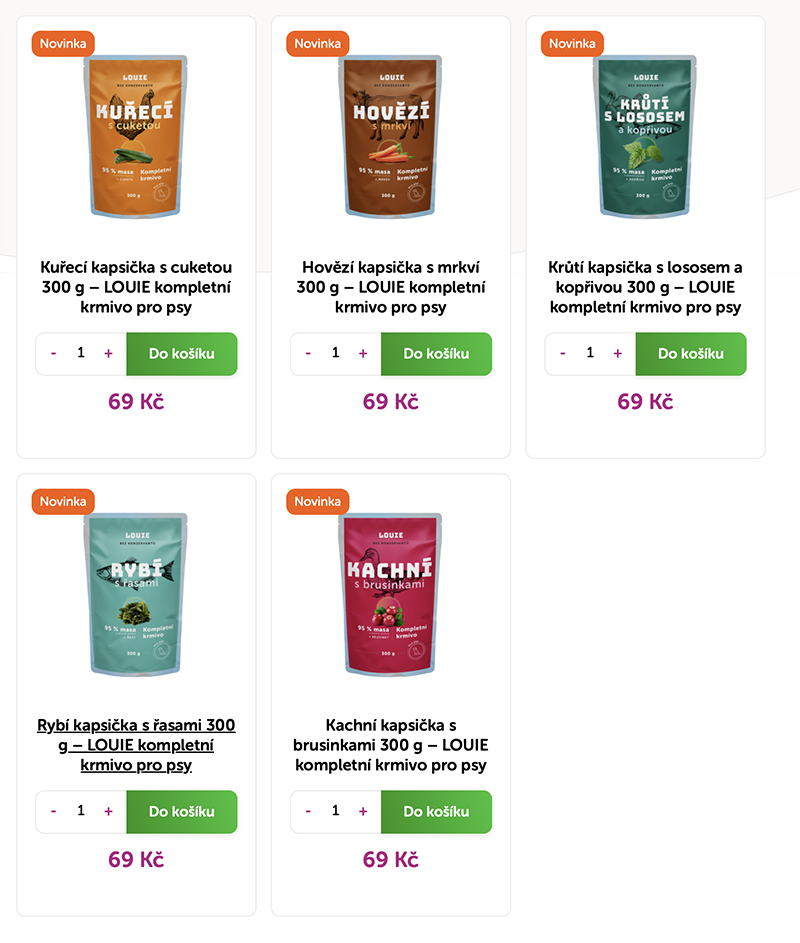

We are filming new advertising campaigns for pouches and Christmas preserves!

Christmas is just around the corner and we have new LOUIE pouches in our range! That’s why we are filming a new commercial to introduce these LOUIE items.

-

New production boiler installed and commissioned!

The increase in production also creates greater demands for sanitation. That is why we have increased the hot water capacity in our production plant in Žabčice by 500 l thanks to a new boiler that works in tandem with the original 200 l boiler and, of course, with the gas boiler.

-

We are also expanding the packaging capacity of our warehouse!

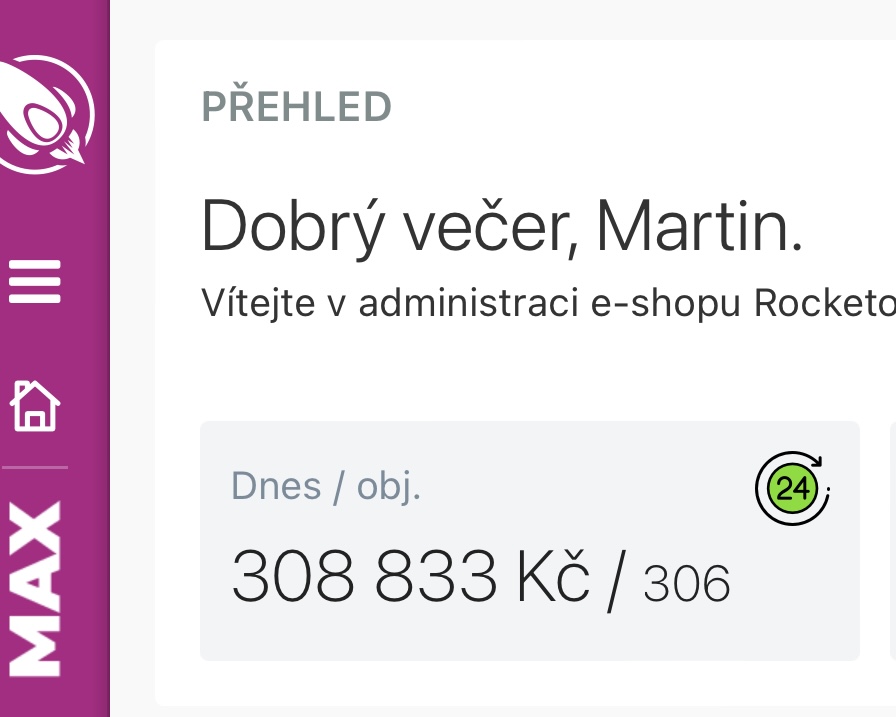

Our packing tables now pick around 300 e-shop orders per day. The remaining part is currently represented by Authentica, but we will soon increase our capacity up to 1000 orders per day!

-

We have increased our warehouse shipping to about 300 orders per day and counting!

In connection with the increase in sales of our e-shops, we have increased the dispatch of our warehouse by 300 orders per day. We are increasing this capacity further!

-

FANTASTIC NEWS! We achieved a turnover of 553 283 CZK PER DAY on our e-shops!

The very first factual steps of our new marketing colleague have incredible results! New campaigns with better creative and graphics were launched on Tuesday, November 19, 2024. The effect came immediately in the form of an increase in daily turnover in CZ and SK to 553 283 CZK! And that’s with a PNO of around…

-

We have launched our own B2C warehouse!

Although we’ve experimented with outsourcing fullfilment B2C contracts over the past year, frankly, we’ve always been disappointed. We’ve tried two partners and both were unreasonably expensive and the service didn’t meet expectations. So in the last 2-3 months we have been working on launching our own B2C warehouse, which we have now put into operation!

-

The new security post of the production plant has arrived

The external security guard of our production plant, which now monitors compliance with the rules and safety of operation 24 hours a day, has a new location. We have received a container gatehouse, where a security officer records the movement of materials and people and lets people in and out of the premises. In addition,…

-

We have received new visualizations of cans for our e-shop

The first step of our new colleague from marketing is to change the visuals of the e-shop and banners. They look much more realistic and eye-catching!

-

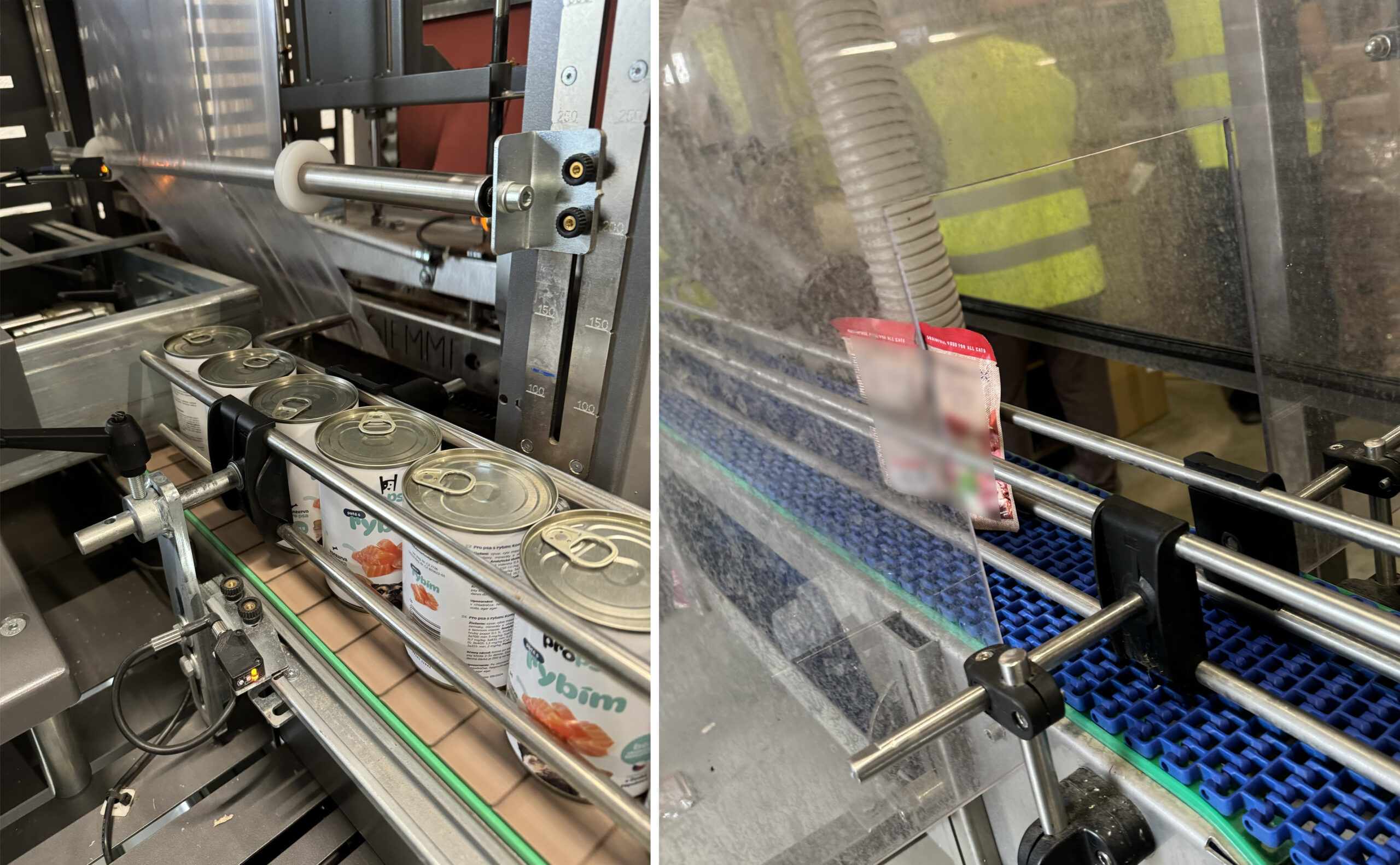

We installed split conveyors

We installed split conveyors, which increased the quality of the inkjet messages printed on the bottom of the cans!

-

We also stock 150 g pouches!

LOUIE pouches in size 150 g are already made and we are currently stocking them! We are expecting a turnaround from this product line, as the small pouch is essentially opening up the treats and rewards segment. While no one is likely to take a tin or a large 300 g pouch on a walk…

-

This is what the mechanism looks like crushing entire 20 kg blocks of frozen meat!

The LASKA frozen and fresh meat slicer, which can grind whole 20 kg blocks of frozen meat to any coarseness, has already arrived!

-

Our business activity report for October 2024!

As we do every month, we have prepared a report on our business activities and progress for October 2024. You can listen to it here: https://youtu.be/X-4_TAauT34

-

We are establishing cooperation with SBS Security

Unfortunately, not all of the “news” that we learn is positive, even if it can be said that the revelation of the problem is a step forward. In recent weeks, we have been dealing with a drop in production on the night shift, which has led us to raid the person who was supposed to…

-

We’ve got another freezer container!

Some time ago we informed you in our news about the plan to install 4 freezer containers for the possibility of holding raw material for the utilization of 4 autoclaves. As part of the implementation of the third phase of the expansion, we have now added a third of these containers!

-

We have started construction of a temporary parking lot!

In order to free up space in the courtyard of our factory for the necessary logistics, we have started building an improvised parking lot on our neighbouring property. If negotiations with the municipality and the county go well, the final finished parking lot could be ready within the next year.

-

We are installing PV on our production site!

Soon we will be saving on electricity. We are installing a photovoltaic power plant on the roof of our plant!

-

We bought a LASKA frozen and fresh meat cutter!

Great news! Today we have reviewed and purchased the LASKA meat slicer! This machine is plenty for all stages of expansion and can cut whole 20kg blocks of even frozen meat, which it grinds to any coarseness.

-

Another bond issue paid!

Today, our holding company paid off another bond issue early to help us kick-start our production operations. In total, we have already paid early for this year’s issues with a total original subscription value of CZK 42,000,000!

-

New handling equipment has arrived at our distribution warehouse in Kuřim!

New handling equipment for our warehouse in Kuřim has just arrived! We are increasing our shipping capacity to supply new chains.

-

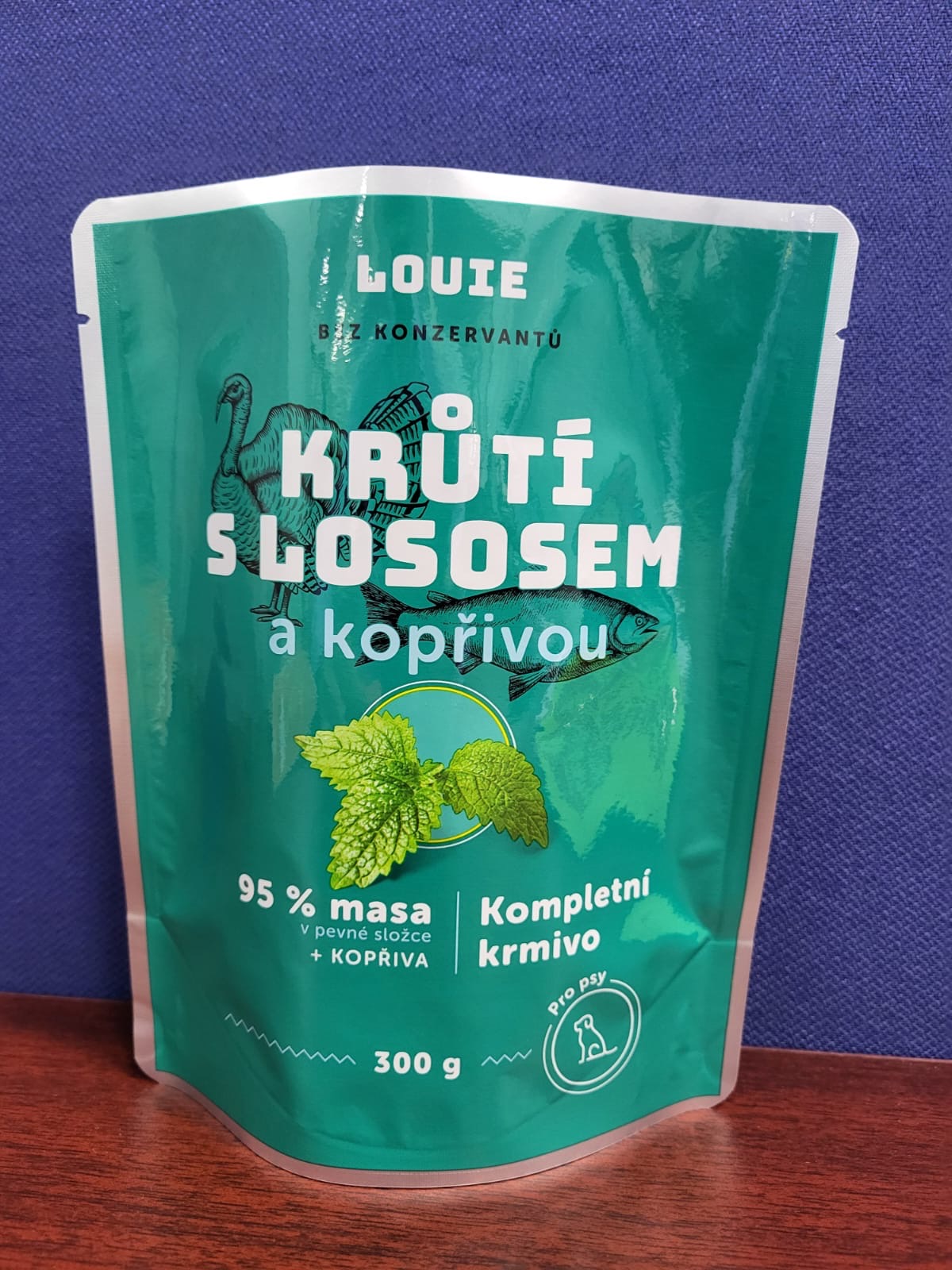

LOUIE pouches on sale!

Since another of our new customers – a chain of about 300 supermarkets in the Czech Republic – has added LOUIE pouches to its assortment, we had the first part of the packaging shipped by air so that we would be able to make the first delivery on time. We have already produced the 300…

-

First delivery of LOUIE to SuperZoo stores left today!

Since the first delivery of LOUIE goods to the central warehouse has already taken place today, we can reveal which new customer of LOUIE goods it was. It is the company Plaček, which operates the SuperZoo network in the Czech Republic and Slovakia, as well as Zoo Kakadu in Poland and Dino Zoo in the…

-

We started both autoclaves at the same time!

Thanks to new orders and orders, we have reached a state of frequent utilization of the current capacities, when both autoclaves are working at the same time!

-

We have obtained the last necessary analyses of coffee oil for submission to EFSA!

In order for our patented oil extracted from coffee grounds to be approved as a new type of food, we still lacked 2 final analyses until recently. Stability analysis and chemical analysis. Both were excellent! There are no pesticides or poisonous substances in our oil and we are therefore submitting the application. We hope for…

-

We are preparing the first ALEMAR investor conference!

In order to better inform our investors about our plans and current status, we have decided to hold the first ALEMAR investor conference on 4 December 2024.

-

Management of marketing activities was taken over by the author of the meteoric growth of Dědoles!

We managed to establish cooperation with the author of the super-successful marketing mix of Dědoles, which managed to increase sales from 250 million to about 2.3 billion in record time. Now he will work on increasing the sales of LOUIE!

-

Another bond issue paid!

Today we have paid off another bond issue within our group early! Specifically, it is the issue used to pay for the production facility in Žabčice.

-

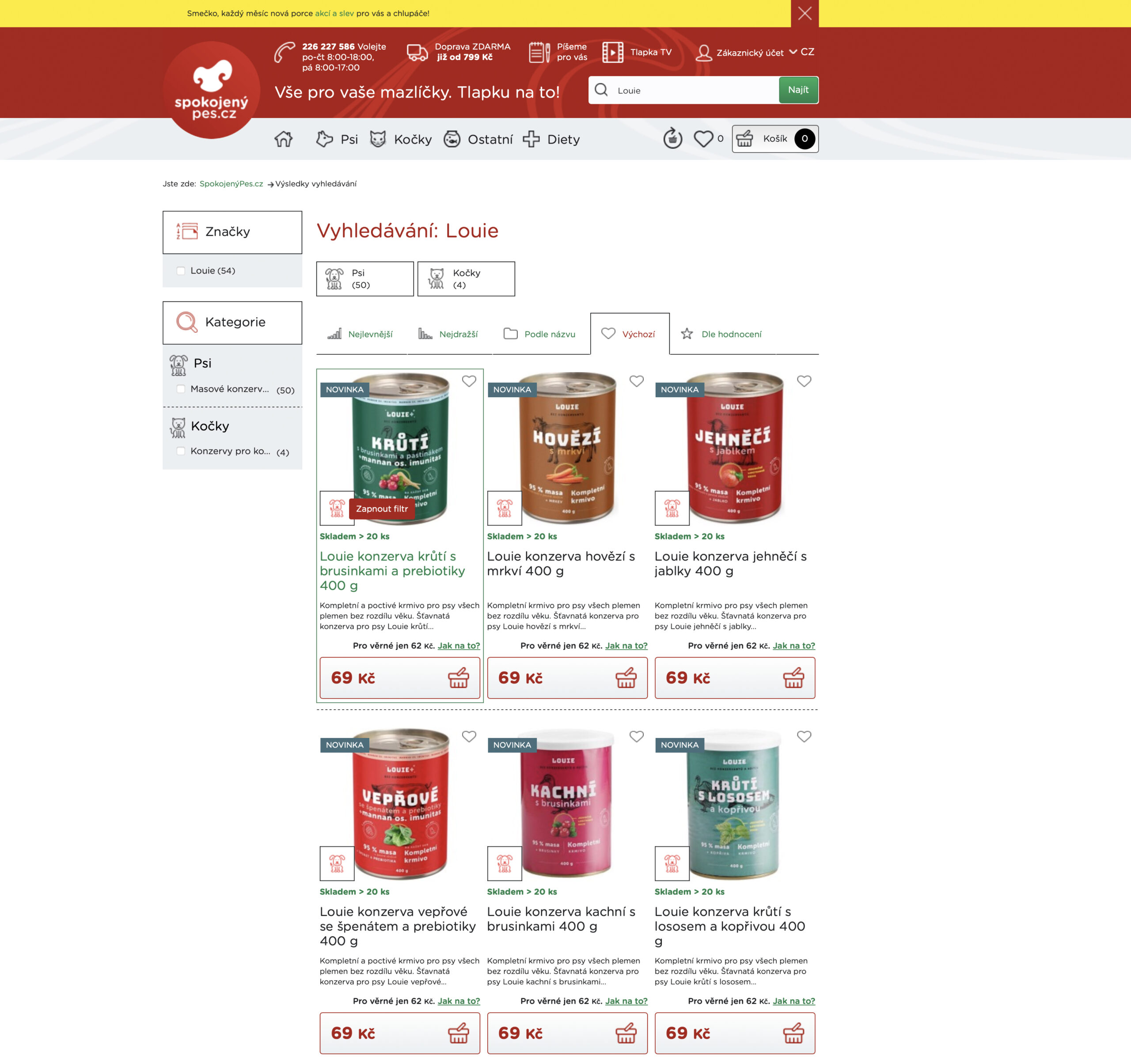

Satisfied Dog has found the goods LOUIE!

The popularity of the LOUIE brand is on the rise, as evidenced by the increased interest from strong retail players in the Pet Business industry. The new LOUIE range has been popularised by the e-shop spokojenypes.cz, which has already generated a turnover of almost CZK 600 million in 2021!

-

We are activating new campaigns and limited editions on e-shops!

Although the overall turnover is growing rapidly due to B2B expansion, in B2C we have improved our year-on-year results in turnover by “only” about 40% in the beginning of October, but the number of orders has even dropped! We attribute this to lower B2C client acquisition and the fact that already established customers are making…

-

We have introduced a simple method of extreme pressure testing!

While the US has developed a special billion-dollar pen for the weightless conditions of spaceflight that writes in all conditions, the Russians use an ordinary pencil. 🙂 This joke reminded us of our new, but workable solution to vetting batches of cans from our suppliers. Since we have recently dealt with the annoyance of a…

-

The secondary part of the production packs the cans and the pouches simultaneously!

Due to the high workload of our production, we have switched to a mode where we pack pouches and cans simultaneously in the secondary part of the production!

-

New compressed air pipelines in operation!

Along with the start-up of the new compressor, we also put into operation new – metal – compressed air distribution lines. Compared to the existing plastic manifolds, they provide better flow, less leakage, but most importantly, the massive air duct balances the pressure fluctuations in the system when running multiple demanding devices at once.

-

New compressor started!

We are very pleased to have launched a new compressor in our production hall! In addition to the dramatic reduction in noise in the production area, the air pressure has also been stabilized with many of the production equipment operating at the same time. This will also allow some of the sterilization phases to be…

-

Business Activity Report for September 2024

As we do every month, we report on business. You can find it at https://youtu.be/F62MnnNaP_M

-

The empty covers for our pouches have been made!

Soon we will introduce our LOUIE pockets, for which we have already arranged a listing in a network of supermarkets in the Czech Republic. Our supplier of empty packaging has already produced them and sent us the first 10,000 of each type by air courier so that we can introduce the product as soon as…

-

We received two custom-made split conveyors

To ensure perfect legibility of the inkjet printed batch numbers, expiration dates, product codes and other information from the bottom of the can, we had two split conveyors custom made with a gap for the inkjet nozzle. They were delivered to us today!

-

We have signed an NDA with a customer asking for 1.8 mil. pcs of cans

This week, a partner with whom we have already signed an NDA regarding the production of their private label will come to Žabčice from far away Spain. This partner is asking us to deliver a total of 1,752,144 canned dog food products by the end of 2024 and during 2025, and these are high quality…

-

From our new partner we expect a turnover of up to 100 000 000 CZK per year!

Last week we informed you about the agreement to list our products in a chain of 450 professional pet supply stores. As we are currently working with a smaller chain that is not as strong in wholesale as our new partner, we have calculated through internal analysis a target turnover with the new partner of…

-

We have planned production for the LIDL chain!

We have included the order for the LIDL chain in our production planning. In a few weeks we will show you photos of our goods directly from the stores.

-

Increase in production to a record stable value!

Due to the volume of newly agreed orders, including LIDL listings, first deliveries for EuroDrink to Ukraine and listings for a new chain with 450 stores in Central Europe, we have increased our stable production volume to 8 autoclaves per shift! So far, the day shift is reaching these figures and the night shift is…

-

Another sales success – listing to a network of 450 stores!

Our sales team uses our production capacities! We have obtained a listing of our LOUIE branded goods with a company that owns 450 of the toppet supply stores in Central Europe!

-

We install a completely new pressurized air system for 3. and 4th phase!

In order to prepare the technical infrastructure for the third and fourth phase of the expansion of production capacity, we are installing a complete new network of ducting, air ducts, filters, dryers and screw compressors to create sufficient quality compressed air.

-

We are launching a project to renovate offices in a neighbouring building

Part of the third phase of the expansion of our production facilities is to designate the space where we currently have offices for storage of empty cans and for a hygiene loop. To enable us to carry out these alterations, we have started a project to move the offices to an adjacent building.

-

We have signed a contract with a new distributor in Ukraine

Today we achieved another sales success by signing a contract for the distribution of our canned brands in Ukraine with EuroDrink, a company that supplies supermarket chains and the independent market in Ukraine.

-

Our work report for August 2024 – we have signed a contract with LIDL!

Just like every month, we have prepared a report on the work of our ALEMAR Food Group team for August 2024. Now we have one great news. We have agreed to cooperate with LIDL and Sportissimo online shop! You can listen to the report here: https://youtu.be/bAxucRwES_U

-

Server iDnes published a podcast with our founder

If you are interested in our business history, concept, plans and goals, you can listen to a podcast with our founder, Martin Košt’ál here: https://www.idnes.cz/ekonomika/domaci/industrial-martin-kostal-alemar-food-group-konzerva.A240614_093738_ekonomika_iape

-

We are starting the system and the weight measurement records to get the “e” mark!

We have previously informed you about the development of guidelines for metrological methodology to obtain registration for the “e” mark. On Friday 23.8. We have introduced this measurement system incl. electronic archiving, we put it into operation. Now all that is left is the approval from CMI.

-

Creating a new MTZ warehouse

Due to the need to reorganize and increase the capacity of our distribution warehouse, we were forced to create a new MTZ warehouse. The transfer of material and equipment to this warehouse has already started! The distribution warehouse in Kuřim will therefore only be used to store goods ready for dispatch.

-

We are expanding our fleet with the Mercedes Atego freezer!

Increasing demands on production capacity also create increasing demands for flexible supply of raw material from external freezers. That’s why we have expanded our fleet with a Mercedes Atego freezer that can transport 7 tonnes of material at a time. This represents up to 40,000 400 g cans, depending on the type of production. This…